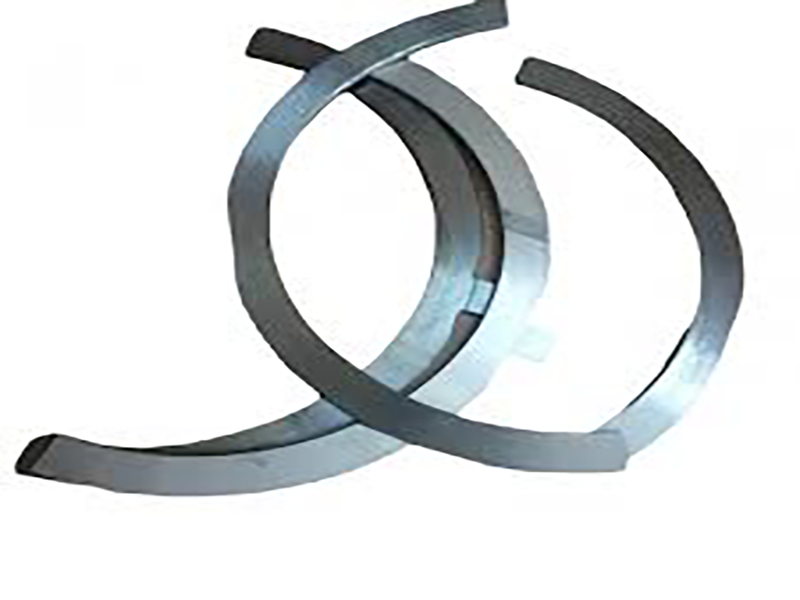

SINOTRUK® Genuine – Thrust Plate – Wearing Parts For SINOTRUK HOWO Part No.: VG1500010125

Basic information

JCHHR supply full range SINOTRUK, HOWO, HOWO PART, HOWO SPARE PARTS,STEYR, WEICHAI,WABCO, WABCO VALVES, WABCO BRAKE PART, SHACMAN, SHACMAN F2000 PARTS, SHACMAN F3000 PARTS, SINOTRUCK, SITRAK spare parts,professional service and good price

HOWO spare parts,HOWO dump truck parts,Original HOWO parts,HOWO truck parts,HOWO A7 truck spare parts,Genuine HOWO truck parts,Original HOWO spare parts,HOWO 371 truck spare parts,

HOWO part, HOWO tipper truck, HOWO 336, HOWO 371, HOWO concrete mixer, HOWO 70T,HOWO 70T mining truck parts, HOVA, HOVA 60, HOVA mining truck, HOVA parts, HOVA 60T, STEYR WD615,Original STEYR spare parts, STEYR 91 series, STEYR dump truck, STEYR WD618, WEICHAI,Original WEICHAI parts, Genuine WEICHAI part, WEICHAI spare parts, WEICHAI WD615, WEICHAI WP10, WEICHAI WP12, WD615,WD615 engine parts, WD615.47, WD615.69, WD615 336hp, WD615 371hp, WD618 diesel engine parts, WD618 420hp, D10 engine parts, D12 engine parts.

Specifications

|

PRODUCT NAME |

VG1500010125 |

OE NO. |

WG1642111014 |

BRAND NAME |

SINOTRUK Howo |

|

MODEL NUMBER |

VG1500010125 |

TRUCK MODEL |

WP10, WP12, WP6, WP7, WP5, WP4, WP3, WD615, WD618 |

PLACE OF ORIGIN |

Shandong, China |

|

SIZE |

Standard Size |

CERICATION |

CCC |

APPLICABLE |

Howo |

|

FACTORY |

CNHTC SINOTRUK |

TYPE |

BELT |

MOQ |

1pc |

|

APPLICATION |

ENGINE SYSTEM |

QUALITY |

High-Performance |

MATERUAK |

Rubber |

|

PACKING |

Standard Package |

SHIPPING |

By sea, By air |

PAYMENT |

T/T |

Relevant Knowledge

The stop washer, also known as the stop washer, commonly known as the Wang Ba gasket, is a type of washer that uses the fit of the stop ear, the opening of the round nut, and the keyway of the shaft to prevent the round nut from loosening. The washer is used in conjunction with the round nut. When used, the washer is installed on the side of the nut groove, and after tightening, the inner and outer stop ears are bent and placed in the groove.

The working principle of the double ear stop washer

In principle, using double ear locking washers to prevent loosening belongs to mechanical locking, which uses various locking parts to prevent the relative movement of tightened threaded parts. This anti loosening method has obvious advantages: reliable anti loosening, complex structure, high space requirements, and needs to be matched during assembly. It is suitable for small batches of difficult to inspect and threaded connections with very strict anti loosening requirements, such as in situations with significant impact, vibration, and high-speed.

Usage of Double Ear Stop Washers

1. Thread the bolt through the double ear stop washer and tighten the thread (when not tightened).

2. Fold down the "long tongue" of the double ear stop washer against the edge of the compressed part.

3. After tightening the hexagonal nut (and the same applies to the hexagonal bolt), stand up the "round ears" of the double ear stop washer, bend them towards the side of the nut and the connected part, and attach them to the side plane of the nut or bolt.

By using the double ear locking washer according to the above method, the nut (bolt) cannot rotate, which can easily achieve the purpose of preventing loosening.