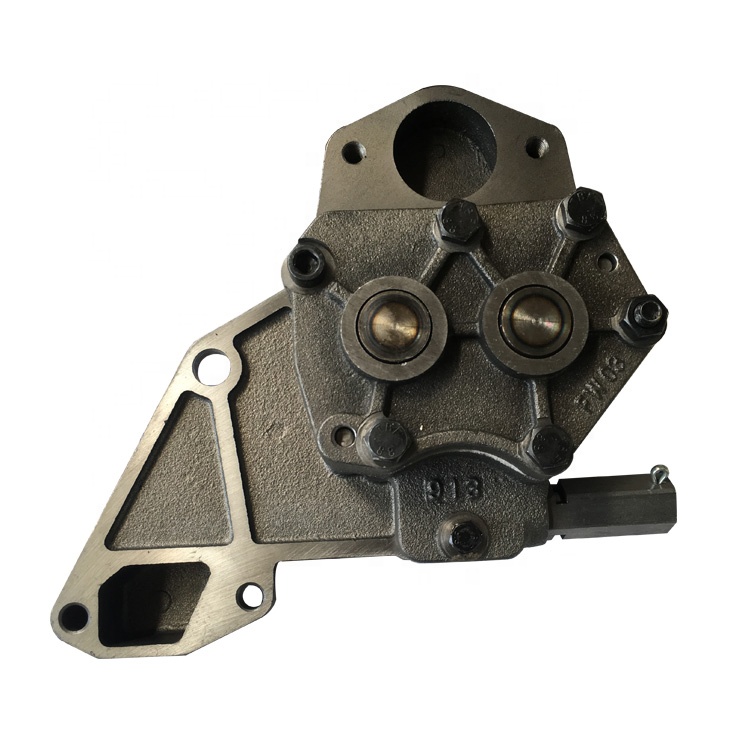

Camshaft Bush Kanggo HOWO, HOWO-T7H, HOWO-A7, SINOTRUK WD615 Series Part No.: VG2600010990/VG1560010029

Informasi dhasar

JCHHR nyedhiyakake macem-macem SINOTRUK, HOWO, HOWO PART, HOWO SPARE PARTS, STEYR, WEICHAI, WABCO, WABCO VALVES, WABCO BRAKE PART, SHACMAN, SHACMAN F2000 PARTS, SHACMAN F3000 PARTS, SINOTRUCK, spare parts lan spareparts sing apik

suku cadang HOWO, suku cadang HOWO dump truk, suku cadang HOWO asli, suku cadang truk HOWO, suku cadang truk HOWO A7, suku cadang truk HOWO Asli, suku cadang HOWO Asli, suku cadang HOWO 371 truk,

HOWO part, HOWO tipper truck, HOWO 336, HOWO 371, HOWO mixer beton, HOWO 70T, HOWO 70T mining parts, HOVA, HOVA 60, HOVA pertambangan truk, HOVA parts, HOVA 60T, STEYR WD615YR spare part, STEYR WD615YR 91 seri, STEYR dump truck, STEYR WD618, WEICHAI, suku cadang WEICHAI Asli, suku cadang WEICHAI asli, suku cadang WEICHAI, WEICHAI WD615, WEICHAI WP10, WEICHAI WP12, WD615, WD615, 6p mesin, 6 p. WD615 371hp, bagean mesin diesel WD618, WD618 420hp, bagean mesin D10, bagean mesin D12.

Spesifikasi

| NAMA PRODUK | Camshaft Bush | OE NO. | VG2600010990/VG1560010029 | JENENG MEREK | SINOTRUK Howo |

| NOMOR MODEL | VG2600010990/VG1560010029 | MODEL TRUCK | WP10, WP12, WP6, WP7, WP5, WP4, WP3, WD615, WD618 | PANJENENGAN ASLI | Shandong, China |

| UKURAN | Ukuran Standar | CERICATION | CCC | APLIKASI | Howo |

| PABRIK | CNHTC SINOTRUK | JENIS | SABUK | MOQ | 1 pc |

| APLIKASI | SISTEM ENGINE | KUALITAS | Kualitas apik | MATERUAK | karet |

| KEMASAN | Paket Standar | PENGIRIMAN | Miturut segara, dening udhara | PEMBAYARAN | T/T |

Kawruh sing relevan

Karakteristik kendaraan camshaft lan cara njaga

Bantalan cam minangka komponen ing mesin piston.Fungsine kanggo ngontrol tumindak mbukak lan nutup tutup.Senajan kacepetan rotasi camshaft ing mesin papat-stroke iku setengah saka crankshaft (ing engine loro-stroke, kacepetan rotasi camshaft padha karo crankshaft), biasane kacepetan rotasi isih banget. dhuwur, lan iku perlu kanggo tahan jumlah gedhe saka torsi.Mulane, ing desain, syarat kanggo kekuatan lan dhukungan saka camshaft dhuwur banget.Bahan kasebut umume wesi tuang khusus, lan sok-sok digunakake forgings.Amarga hukum gerakan katup ana hubungane karo daya lan karakteristik operasi mesin, desain camshaft nduweni peran penting ing proses desain mesin.

1、Struktur bantalan cam

1. Struktur gabungan saka bantalan roller jarum ring njaba lan bolt

2. Ukuran kasedhiya ing seri metrik lan Inggris

3. Bolt bantalan diwenehake karo lenga pelumas

4. Kanggo nggampangake instalasi, mburi gedhe saka prewangan dirancang karo "slotted" lan "bolongan hexagon" cara perakitan wrench

5. Lumahing njaba dering njaba duwe bentuk silinder lan bunder, sing bisa dipilih miturut aplikasi praktis

6. Tipe roller lengkap cocok kanggo aplikasi kanthi beban dhuwur lan kecepatan rotasi sing kurang

7. Tipe eksentrik bisa kanthi gampang lan akurat nyetel posisi sumbu bolt nalika nginstal bantalan

2、Carane njaga bantalan cam

(1) Priksa kelengkungan camshaft.Kanthi jurnal ing ujung loro minangka fulcrum, runout radial kudu ora luwih saka 0,03 mm, lan yen ngluwihi 0,10 mm, bisa didandani nggunakake metode koreksi tekanan dingin.

(2) Nalika angkat cam ora kurang saka 5% saka nilai kasebut, diijini ora tlatah cam, nanging bunder dhasar cam lan toleransi runout bunder radial bunder dhasar cam kanggo sumbu camshaft kudu. dipriksa;Standar overhaul yaiku

0.03mm, mrikso diijini ora luwih saka O.05mm.

(3) Lumahing cam kudu dipoles yen kasar, rusak, utawa diadu.Nalika nyandhang tip cam ngluwihi 1.00 mm, tip cam kudu didandani sawise surfacing welding kanggo mulihake ukuran asli lan wangun,

utawa ngganti.

(4) Yen lumahing pindah saka gear drive pump lenga ing camshaft atos utawa rusak luwih saka 0,50 mm, iku kudu didandani.untu individu saka pindah rusak, lan iku allowe

Terusake nggunakake sawise nggiling sudhut sing cetha.Kekasaran permukaan roda eksentrik pompa transfer bahan bakar ora kudu ngluwihi O.80 μm.Nalika nyandhang saka rodha eksentrik ngluwihi 2,00 mm, camshaft kudu didandani utawa diganti dening lumahing welding.

(5) Toleransi silinder saben jurnal camshaft: standar overhaul yaiku 5 μm.Tunjangan overhaul ora luwih saka 15 μm.Watesan panggunaan yaiku 25 μm.

(6) Toleransi radial circular run-out saka jurnal poros lan kesalahan run-out circular pasuryan mburi saka pasuryan mburi dorong aksial saka gear timing camshaft ora luwih saka 35 μm